In the 1989 film Back to the Future: Part 2, Marty McFly arrives in the year 2015 to find self-lacing sneakers and jackets featuring built-in computers, auto-adjusting sleeves and jet-drying functions that eliminate the need for towels.

While the present day may not have caught up with Marty just yet, faculty and students at the Textiles Nanotechnology Laboratory at Cornell University are working hard to make fantasies like these into realities.

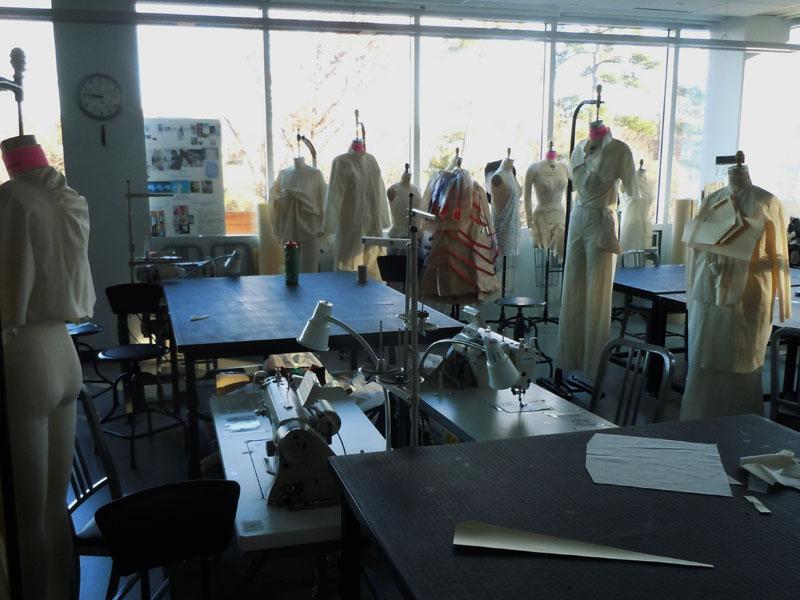

Every spring, the Cornell Fashion Collective puts on a professional runway exhibition to showcase student work. The April 2014 show will mark the 30th straight year of student competition, including those who work on fashion design and others who researching scientific applications for their pieces.

[swfobject]2370[/swfobject]

Due to the the proximity of facilities in the Department of Fiber Science and Apparel Design, students in both are able to work with together to apply their inventions in real-world situations. Juan Hinestroza, associate professor of fiber science, said he has a combination of undergraduate students working on fashion design and graduate students working on the theory elements of clothing.

In many hospitals, patients who are not critically ill may have to sit in waiting rooms before a doctor can see them. They may also be instructed to put on a disposable mask if they are coughing to prevent the spread of germs. Margaret Frey, another professor in the department, said she is conducting research into making this process more efficient and less time-consuming.

Frey said that when properly engineered, certain fibers in the masks could be used to capture bacteria for sampling and make diagnosis easier for doctors and patients.

“Instead of having a swab rammed down your throat, they could just analyze the mask to see what illness you have,” she said. “Then it makes your time sitting in the waiting room actually useful, and you can avoid any personal discomfort.”

Thermochromic pigments or polymers can be applied to a fabric, and change color with temperature. This effect is being applied to activewear and being used to gauge the body’s temperature change. This is a feature that may be very useful for tracking athletes who may be exercising to a point of physical exhaustion. Eric Beaudette said he is focusing on this topic for a project team, along with Sarah Meyers (’16) and Ariana Levitt (’15) for the upcoming fashion show.

Cornell is not the only school interested in this field of research. North Carolina State University was founded as a school of textiles in 1887, and today its College of Textile Engineering, Chemistry and Science is still one of the leaders in the field of fiber science.

But the textile industry also has a dark side. Each year, students are taken to India to see conditions in manufacturing centers and production facilities, as well as pollution caused by the fiber industry.

Hinestroza said that remaining environmentally conscious is important to the department as well.

“There are some places [in India and China] where you can guess what color is in fashion in the U.S. or in France just by the color of the river – this is the river people drink from,” he said.

The department is working on fibers that can mitigate these issues by straining toxins out of liquids, Hinestroza said. This could even be done by re-engineering denim products with certain chemical treatments.

“I’d like to see a cycle in this,” Hinestroza said. “You contaminate while making the jeans, and now you can use your old jeans to clean up the water.”